Advantages

• Preserves Flour Freshness & Quality

Built-in oxygenation system keeps flour fresh and improves storage stability.

• Boosts Production Efficiency

Automated transfer and handling enable higher throughput with minimal labor.

• Enhances Water Absorption & Product Quality

Air-based transfer oxygenates the flour, improving water absorption and final product softness.

• Continuous Flow for All Flour Types

Vibrating cone system ensures consistent flour discharge—even with low-fluidity flours.

• Cuts Sack Costs & Packaging Waste

Direct filling via silo truck eliminates the need for bagged flour and reduces operational costs.

• Saves Space & Labor

Compact vertical design with automated feeding reduces footprint and manual handling.

Optional Add-Ons

• Vibrating discharge cone

• Jet filter system

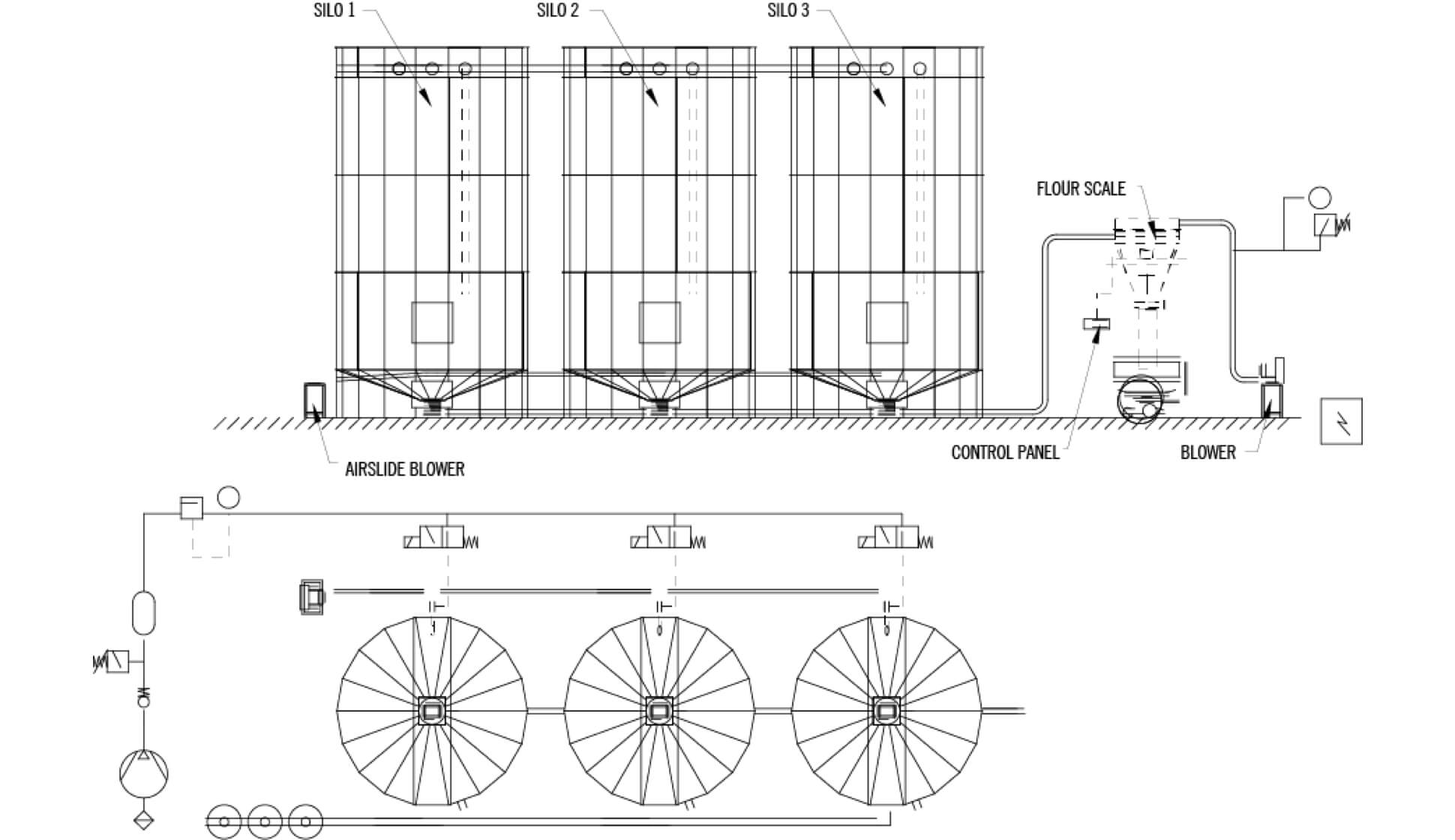

• Automatic silo weighing module

• Integration with flour weighing stations

• Sack loading and in-line sieving unit

• Inline magnetic separator and safety sieves